Realization: 2011 – 2013

Number of PE: 126 400

Client: Liptov water company, joint-stock company

Value of works: 9 077 166,– EUR

WWTP Liptovský Mikuláš was put into operation in 1975 as a mechanical- biological WWTP. In 1989 biological step was intensified and sludge and gas management were completed as well. In 2011 started a significant reconstruction of whole plant. After this reconstruction is WWTP working as a mechanical-biological plant with nutrients removal, a chemical phosphorus precipitation by ferric sulfate solution. Sludge management consists of anaerobic sludge stabilization and utilization of produced biogas for the energy needs of the plant.

The mechanical step consists of a grit chamber, screenings and two aerated sand and grease traps, and two primary sedimentation tanks (radial and longitudinal). Storm waters are partly relieved to recipient before and then also after the mechanical step.

The biological step consists of a cascade activated sludge system (36 000 m3) and a sludge regeneration (3 000 m3). The cascade activated sludge system is serially arranged in three tanks of denitrification/ nitrification (6 400 m3, 8 000 m3, 21 600 m3) with wastewater inflow in different ratio (20%, 25%, 55%). Organic substrate – methanol is added to enhanced denitrification. Industrial wastewater coming to WWTP Liptovský Mikuláš is from leather industry and from pork, beef and fish gelatin production. Specifically because of this atypical composition of incoming wastewater there is a need of phosphorus addition (phosphoric acid) in some period of year.

The air for nitrification and regeneration is delivered by rotary blowers (2 x 21 000 m3/h) in dependency of an online measurement of dissolved oxygen concentration or ammonium nitrogen concentration. After the nitrification sections the biologically treated water with activated sludge flows to four radial secondary clarifiers (3 056 m3) for separation. From secondary clarifiers the treated water flows to recipient which is in this case the dam Liptovská Mara.

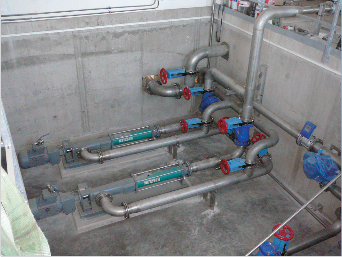

The sludge management consists of two anaerobic stabilization tanks (10 600 m3) operated under mesophilic conditions, mechanical thickening of biological excess and primary sludge and dewatering of anaerobically stabilized sludge. Anaerobic stabilization tanks can be operated in serial or in parallel arrangement. The anaerobic stabilization tank is mixed by pneumatic mixing with produced biogas by rotary compressors or alternatively by hydraulic mixing with a pump.

A biogas produced in anaerobic stabilization tank is stored in dry two membrane gasholder. These membranes are made of high resistant polyester fabric coated with PVC. The biogas is preferably used as a fuel to produce electricity in cogeneration unit for the needs of WWTP and created heat is used for the heating of sludge in anaerobic stabilization tank. In the boiler room is produced heat from the biogas to heat buildings in winter time. The excess biogas is burned in a gas burner.

The measurement and control of the main technological processes is ensured by an on-line measurement of ammonium nitrogen, nitrate nitrogen, dissolved oxygen and phosphate phosphorus in biological step or at the outlet of the WWTP.